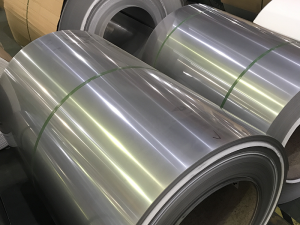

410S Gariiradda Birta Aan Lahayn

Sharaxaada

Tilmaamaha:

1.Standard: ASTM A240, JIS G4304, EN10088

2. Fasalka: 200 taxane&300 taxane&400 taxane ah

3. Dhumucda: 0.03mm - 6.0mm

4. Ballaca: 8mm-600mm

5. Length: sida codsiga macaamiisha

6. Dusha sare: 2D,2B, BA, Muraayad dhammaatay, N04, Xariiqda timaha, Matt finish, 6K, 8K

7.Technology: qabow la sawiray / qabow duuban / kulul duudduubay

Qalabka:

| Nooca | Darajo | Darajo | Qayb kiimiko % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Mid kale | |||

| Austenitic | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50 - 7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Macluumaadka aasaasiga ah

410s Gariiradda birta ah, oo leh iska caabin daxalka wanaagsan iyo machinability, waa ujeedada guud ee birta iyo qalabka goynta birta.410S waa nooc ka mid ah birta kaas oo hagaajin kara iska caabbinta daxalka iyo qaabaynta 410 steel.410S waa bir xoog badan oo sii wanaajin karta iska caabinta daxalka ee 410 birta.Waxaa loo isticmaalaa marawaxadaha marawaxadaha iyo qaybaha heerkulka sare.

• Tilmaamaha: AISI 410s, ASTM 410s

• Dhamaystir: Ba dusha sare, 2b dusha sare, No.1 (maqaarka cad), 2D dusha, No.4 (barafaysan), HL (sawir silig), 8K dusha sare leh tayada sare

• U dulqaadashada dhumucda iyo fidsanaanta ayaa khuseysa. Wac JM Steel haddii aad u baahan tahay qiyaaso gaar ah ama jihada hadhuudhka.

410S Tignoolajiyada mashiinada sifada

1D -- Dusha sare waxay leedahay qaab granular ah oo joogsan, oo sidoo kale loo yaqaan dusha ceeryaamo.

Tignoolajiyada farsamaynta: rogid kulul + xoqida toogashada qajaarka + duubista qabowga

2D - Midab cad oo xoogaa qalin ah.

Tignoolajiyada farsamaynta: rogid kulul + xoqida toogashada qajaarka + duubista qabowga

2B -- Caddaan qalin ah oo leh dhalaal iyo siman ka wanaagsan oogada 2D.

Tignoolajiyada habaynta: rogid kulul + rogid xabagta toogashada + qajaarka qabow + qallajinta daminta

Ba - dhalaalid sare oo heer sare ah, sida muraayadda oo kale.

Farsamaynta farsamaynta: rogrogmida kulul + rogid rogid ah + rogid qabow + qashin-qaadid qabow + dhalaalid dusha sare + deminta iyo rogrogga xanaaqa.

No.3 -- dhalaal wanaagsan, oogada sarreenka oo aan dhab ahayn.

Tiknoolajiyada farsamaynta: dhalaalidda iyo is-dul-qaadashada 2D ama 2B oo leh 100 ~ 120 walxo abrasive ah (JIS R6002).

No.4 -- dhalaal wanaagsan, xariijimo fiican oo dusha sare ah.

Habka habaynta: dhalaalid iyo dabci rogid loogu talagalay 2D ama 2B oo leh 150 ~ 180 walxaha abrasive (JIS R6002).

HL -- Qalin cawlan oo timo timo leh.

Farsamaynta farsamaynta: Alaabooyinka 2D ama alaabada 2B oo leh granularity ku haboon ee alaabta xoqida si loo nadiifiyo dusha sare waa hadhuudh xoqan oo joogto ah.

MIRRO -- Specular.

Farsamaynta farsamaynta: Alaabooyinka 2D ama alaabada 2B oo leh granularity ku habboon shiidida walxaha wax lagu shiidi karo iyo sifaynta saamaynta muraayadda.